- Introduction

Introduction

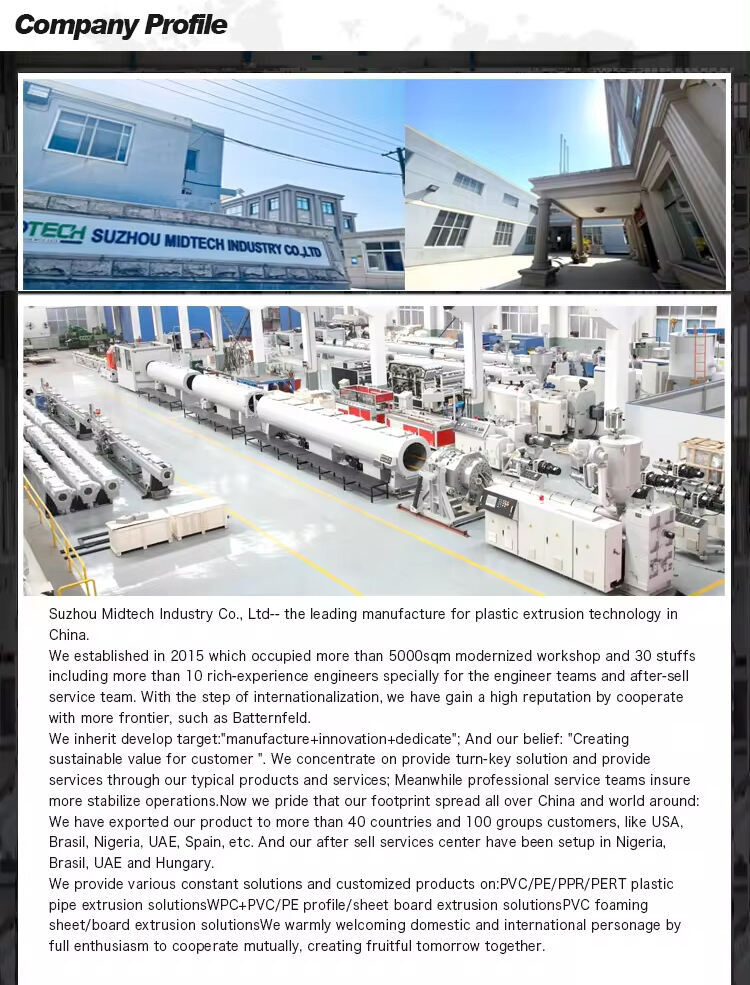

Presenting the Plastic PVC Floor Board Decking Machine from MIDTECH - a state-of-the-art equipment that is made for cost-effective and manufacturing that is efficient of PVC decking boards.

Crafted with precise engineering, the MIDTECH PVC Floor Board Decking Machine supplies a reliable and design that is sturdy boasts exceptional durability and longevity. It is the device that is ideal manufacturers that seek to produce top-quality PVC decking boards at a cost that is acceptable without compromising on innovation and gratification.

The device features a control that is advanced that guarantees optimal operations, creating high-quality floorboards in just minimal waste. The MIDTECH PVC floors device is equipped with a motor that is efficient enables a high-speed manufacturing rate, fully customizable to fit the initial needs of the production procedure. Alongside its interface that is easy-to-use of this decking device is hassle-free, helping you to consider other important areas of your manufacturing line.

Also, this revolutionary product boasts a design that is versatile can support multiple PVC formulations, therefore you can perform variations of color, texture or patterns to match your customers' requirements. The MIDTECH PVC Floor Board Decking Machine are designed for it whether you are looking to generate items for the residential or commercial room.

This machine is low-maintenance, and that means you won’t want to concern yourself with extortionate breakdowns or downtime inside your operations with regards to of maintenance. The device is created using the quality components that are greatest being resistant to hold and tear, making it possible for efficient and manufacturing that is dependable again and again. Also, the equipment is easy and quick to totally clean, making your cleaning process a complete lot more manageable.

Safety can also be a problem in terms of the MIDTECH PVC Floor Board Decking Machine. It comes down with safety features that ensure the wellbeing of operators, reducing the incidence of accidents as well as other hazards. This implies peace of mind for you personally with your employees.

|

Model

|

Max width

|

Extruder model

|

Motor power

|

Max capacity

|

|

YF 180

|

180mm

|

SJSZ 51/105

|

22 KW

|

120 kg/h

|

|

YF 240

|

300mm

|

SJSZ 65/132

|

37 KW

|

260 kg/h

|

|

YF 600

|

600mm

|

SJSZ 80/156

|

55 KW

|

400 kg/h

|

|

YF 800

|

800mm

|

SJSZ 92/188

|

90 KW

|

650 kg/h

|

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ