- Introduction

Introduction

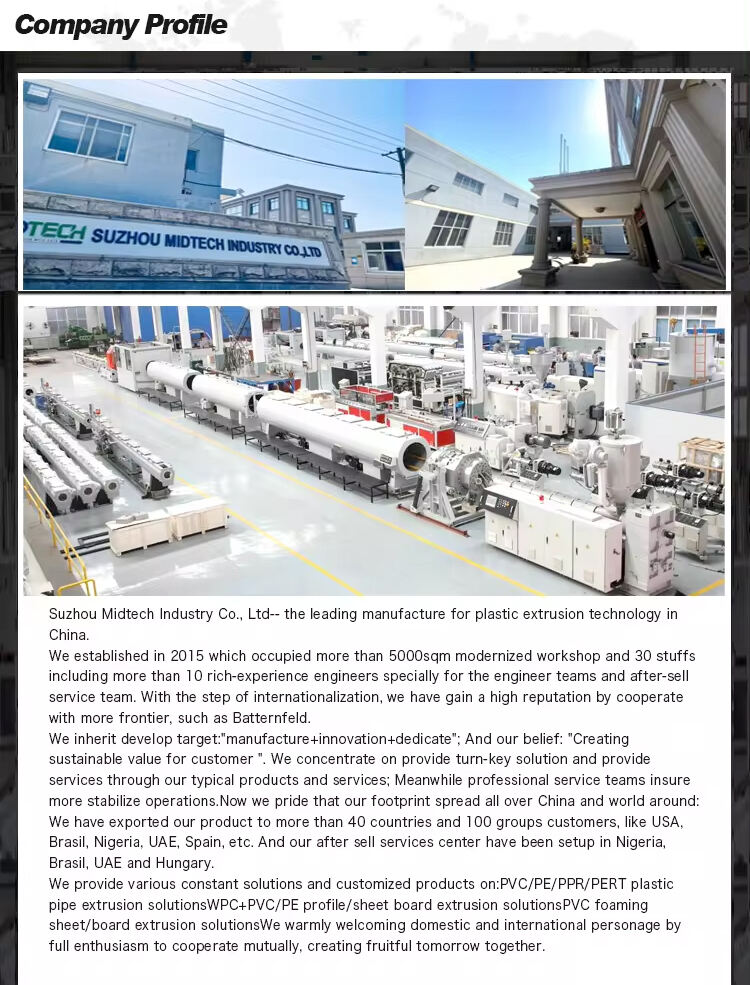

MIDTECH

Pet Bottle Recycling Line/Waste Plastic washer could be the perfect solution for recycling synthetic waste and maintaining a breeding ground is eco-friendly. It gives a cutting-edge and method is certainly efficient cleansing and reusing synthetic bottles and waste materials. This machine is built to effectively eliminate all contaminants, including labels, caps, glue, dirt, and oil from PET containers.

The Pet Bottle Recycling Line/Waste Plastic washer is not difficult to utilize and is loaded with more impressive range technology for the washing is certainly perfect drying of plastic bottles and waste products. The device uses water is high-pressure thorough cleaning and efficiently removes all dust and impurities. Using this device, it is possible to reduce waste, conserve resources, and protect the surroundings are environmental saving money.

This recycling line comes with a sorting is automatic that separates the materials, eliminating the requirement for manual sorting. The additional product is collected and place to reuse, preventing wastage. Also, the unit is eco-friendly and contains no influence on the surroundings since it ensures disposal is certainly proper of material. It is possible to decide for modification to suit your requirements and specs.

MIDTECH's Pet Bottle Recycling Line/Waste Plastic Washing Machine is of superior quality and it is made making use of materials that are high-grade durability. The equipment is made to final and withstands use this is certainly frequent. The company provides customer that is quality and help to ensure you've got a seamless experience while utilizing their product.

Utilizing MIDTECH's Pet Bottle Recycling Line/Waste Plastic Washing device guarantees decreasing the amount of synthetic waste into the environment. This revolutionary product will work for use within recycling, waste management, and preservation this is certainly ecological. You can efficiently transform waste that is synthetic reusable items in host to contributing to the waste in the environment. Employing this recycling line, in addition, you promote residing and sustainable is certainly accountable.

Material:Variegated bottles

Function:To separate PET bottles to flake from PE/PP label, cap, oil, garbage, protect the environment, avoid white pollution.

Technical flows:

Belt conveyer→ mechanical label separator→ manual sorting→ metal detector→ belt conveyer→ wet crusher→ screw conveyer→ floating washer→ screw conveyer→ hot washer→ screw conveyer→ high speed friction washer→ screw conveyer→ floating washer→ screw conveyer→ vertical dewatering machine→ drying system→ zigzag label separator→ storage silo---operating panel

|

Capacity option

|

500KG/H

|

1000KG/H

|

2000KG/H

|

||

|

Workshop(m*m*m)

|

42*10*6

|

55*15*6

|

70*18*6

|

||

|

Staff

|

6 persons

|

8 persons

|

12 persons

|

||

|

Water consumption

|

2 T/H

|

3.5 T/H

|

10 T/H

|

||

|

Final products

|

Moisture: max 1%

Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

||||

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ