MIDTECH Twin Screw Extruder Plastic PVC Ceiling Wall Panel Making Machine

Product Brochure:DOWNLOAD

- Introduction

Introduction

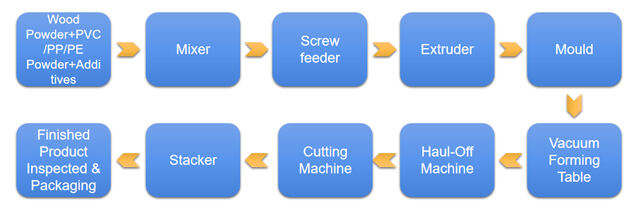

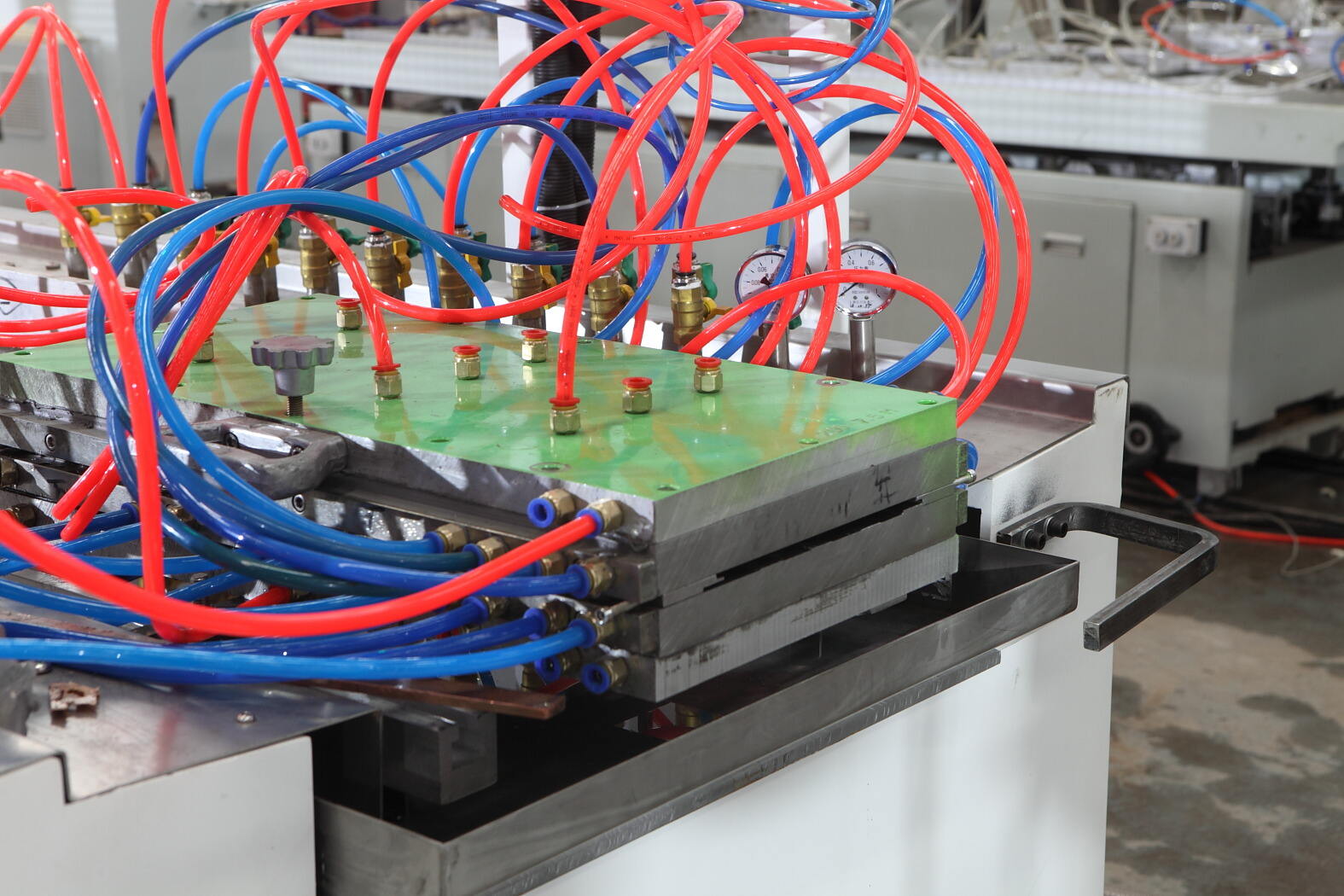

Looking for a reliable and device this is certainly durable will help you to produce PVC that is top-quality ceiling wall panels? Look no further than MIDTECH's Twin Screw Extruder vinyl PVC Ceiling Wall Panel device that is generating. This machine is designed with accuracy, using technology that is advanced ensure optimal effectiveness and gratification.

This revolutionary product works well at producing PVC ceiling and wall panels with constant thickness and uniform quality with its double screw design. It is strong and screws that are durable will handle high volumes of PVC product, ensuring a regular and production process that is seamless.

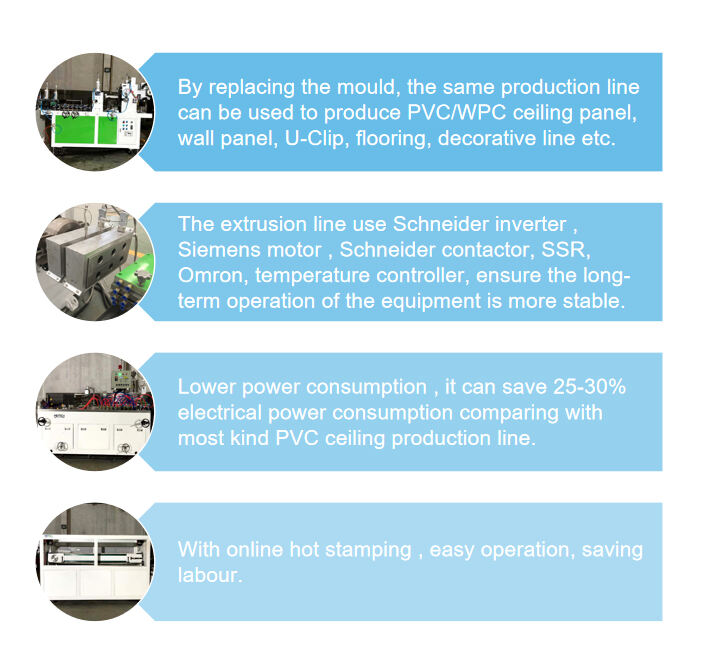

The MIDTECH Twin Screw Extruder Plastic PVC Ceiling Wall Panel Making Machine is simple to operate, making it an option that is great both novices and manufacturers that are experienced. It really is laden up with a control that is user-friendly enabling you to definitely adjust the apparatus settings, such as the rate associated with the screws plus the temperature in connection with heating elements, effortlessly and quickly. This guarantees you have the apparatus that you could achieve the required outcomes every time.

Another function that is very good of device is its high effectiveness. It could produce up to 400 meters of PVC wall surface and roof panels each full hour, and that means you can manufacture large degrees of panels quickly and effortlessly. This makes it an investment this is certainly excellent you want to improve your manufacturing capability and optimize your profits.

The MIDTECH Twin Screw Extruder Plastic PVC Ceiling Wall Panel Making Machine can be built to final. It is created using top-notch materials being resistant to wear and tear, ensuring durability that is long-term reliability. This implies you should use the machine for decades as time goes by without fretting about it wearing down or repairs that are needing are regular.

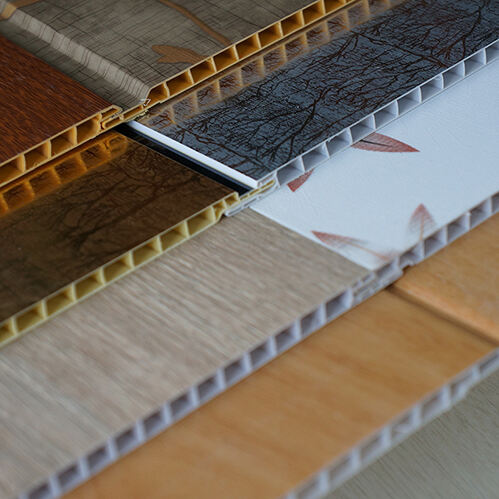

One of the best benefits of this machine would be the fact that it can be custom made to meet up your needs that could be needs that are specific. You will choose from different screw sizes, extrusion dies, along with other features to create PVC panels in a variety of sizes, thicknesses, and designs. This implies you can tailor your production process to generally meet with the needs for the clients and the market.

Model | Max width | Extruder model | Motor power | Max capacity |

YF 180 | 180mm | SJSZ 51/105 | 22 KW | 120 kg/h |

YF 240 | 300mm | SJSZ 65/132 | 37 KW | 260 kg/h |

YF 600 | 600mm | SJSZ 80/156 | 55 KW | 400 kg/h |

YF 800 | 800mm | SJSZ 92/188 | 90 KW | 650 kg/h |

1)Upper/lower caterpillar driven separately and speed control

Q1. Are you manufacturer or trading company?

We are the manufacturer and trading company. We have many years of experience. We can guarantee the quality of products and good after-sales service. Welcome to consult.

Q2. How should I pay for my order?

30% as down payment by T/T;70% by T/Before delivery and after inspection.

Q3. How long is the delivery time?

40 working days since the date of receiving down payment.

Q4. How is the machine warranty and after-sale service?

13 months since date of bill of lading. During the guarantee period, MedTech will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, MedTech will provide the buyer spare parts at cost price.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ