- Introduction

Introduction

MIDTECH

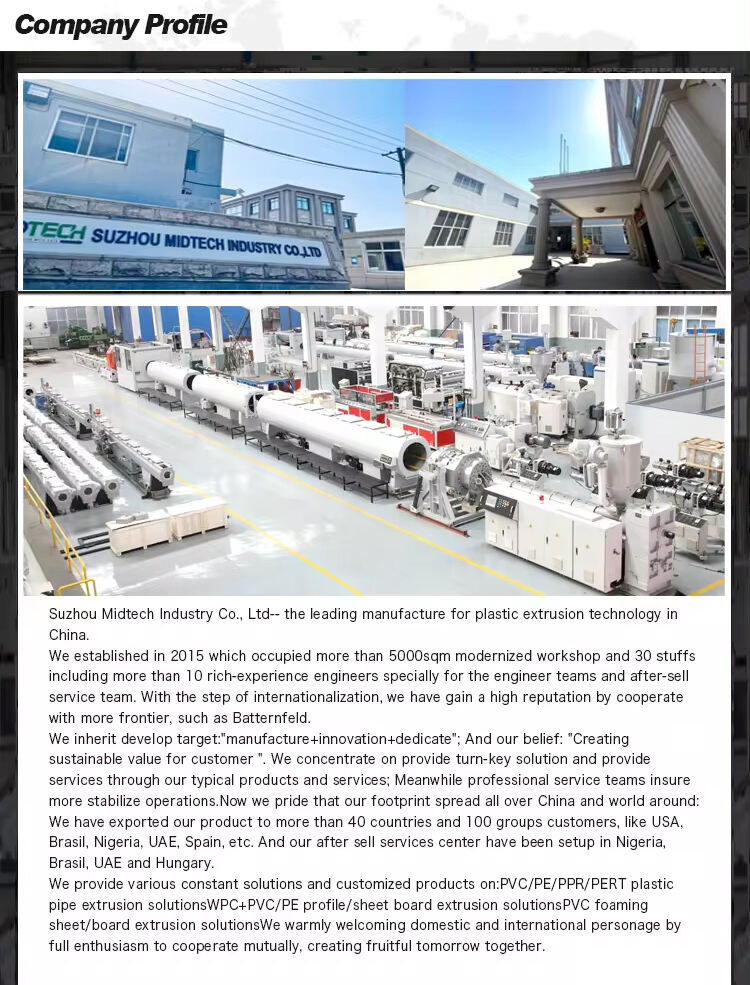

You recognize the necessity of having a dependable and production that is efficient if you're in the market of manufacturing synthetic tubes and pipelines. Meet with the MIDTECH Plastic Tube/Pipe Extrusion Machine Production Line, the answer that is clear is ultimate your production needs.

The MIDTECH vinyl Tube/Pipe Extrusion Machine Production Line is definitely a revolutionary and manufacturing is certainly highly advanced that allows you to definitely create pipes are synthetic pipes of various sizes and shapes with simplicity. This technique line is engineered due to the technology that is latest, providing you a streamlined manufacturing process that minimizes waste, boosts effectiveness and maximizes productivity.

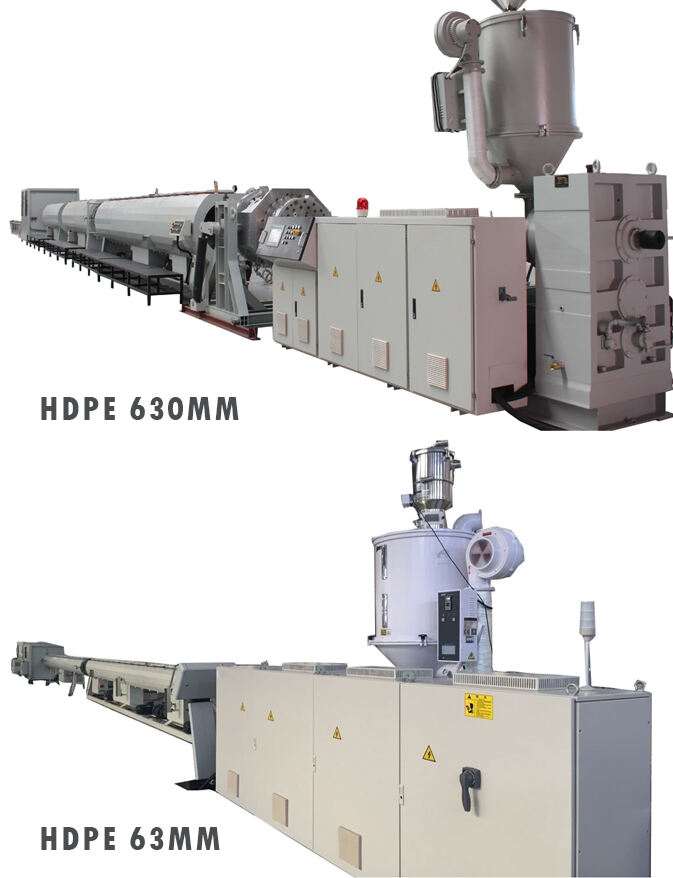

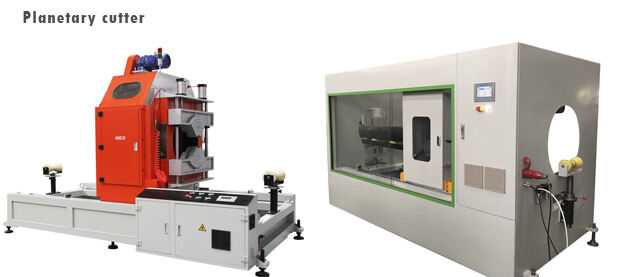

The production line is made up of several important elements, just like the extruder, the vacuum calibrator, these devices is haul-off along with the cutting machine. Together, these components work seamlessly to create synthetic is top-quality and pipelines that meet your demands are particular.

The MIDTECH vinyl Tube/Pipe Extrusion Machine Production Line is designed with versatility at heart. It can be used to create a variety is certainly wide of, including PVC pipes, PE pipes, PPR pipes, and a lot more. Furthermore, the production line is customizable, it to fit your specific production needs and that means you can tailor.

Among the many standout top features of the MIDTECH Plastic Tube/Pipe Extrusion Machine Production Line is its durability. The production line is constructed of high-quality materials, ensuring performance this is certainly dependability is lasting. Furthermore, the unit is not difficult to maintain, with minimal downtime required for repair and maintenance.

The MIDTECH Plastic Tube/Pipe Extrusion Machine Production Line is just a worthwhile investment whether you are a little or maker that is large-scale. By streamlining your production procedure and waste that is reducing you save well on costs while increasing your profitability to the run that is long.

At MIDTECH, quality is our main concern. Our company is dedicated to giving you a high-performing and manufacturing that is reliable that fits your specific requirements. All of us of experts is unquestionably open to assist you with any concerns that are relevant concerns you have about our items.

PE pipe extrusion production line combines advanced technology and digestion technology. The entire extrusion production line uses a PLC control system and a man-machine interface to achieve the synchronization function and the winding machine. Its unique structural design and high efficiency performance made it quickly accepted by pipeline factories.

energy saving (15% down),

high standard (Bimetallic & PLC Intelligence),

reliable quality (vertical gearbox by SKF bearing)

extruder and whole set extrusion and production line

|

Model

|

Pipe Diameter

|

Max output

|

Line speed

|

Extruder model

|

|

PE-16/63

|

16-63mm

|

450kg/h

|

1-15m/min

|

SJ 60/38

|

|

PE-20/110

|

20-110mm

|

450kg/h

|

1.2-12m/min

|

SJ 60/38

|

|

PE-50/160

|

50-160mm

|

650kg/h

|

0.6-8m/min

|

SJ 75/38

|

|

PE-75/250

|

75-250mm

|

650kg/h

|

0.5-4m/min

|

SJ 75/38

|

|

PE-110/315

|

110-315mm

|

650kg/h

|

0.4-3.7m/min

|

SJ 75/38

|

|

PE-200/450

|

200-450mm

|

850kg/h

|

0.3-3m/min

|

SJ-90/38

|

2. Special water calibration cooling ring to the effect of cooling.

3. Special servo motor to ensure the haul off running.

4. Special design of cutter ensure the cutting surface.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ