Best 5 Manufacturers for Plastic Extruder

Plastic is truly a material versatile and is widely employed in various companies. An extruder synthetic will become necessary to enable you to produce synthetic products. A plastic extruder is a tool that melts and shapes synthetic materials to be in various forms. Here in MIDTECH, we are going to introduce the 5 most effective manufacturers for plastic extruder devices. These manufacturers provide high-quality items with exclusive advantages, innovative designs, and solution excellent. Let’s have a closer look at all of them.

Great things about Plastic Extruder

Plastic extruders provide several advantages, such as for instance efficiency, high accuracy, and versatility. A number is produced by the extruder wide of products and services with various shapes and sizes. The equipment can also process plenty of various plastics, including PVC, HDPE, LDPE, amongst others. The extruder is easy to function and requires maintenance minimal rendering it a cost-effective choice for synthetic item manufacturers.

Innovation in Plastic Extruder

Innovation is just one factor is key to the growth and search of plastic extruders. The best manufacturers utilize more impressive range technologies to boost the quality and performance of these items. They integrate features such as automatic controls, accuracy temperature control, and design this is modular. These innovations assure higher efficiency, accuracy, and security whenever you glance at the extrusion procedure.

Security Considerations for Plastic Extruder

Security is a priority on top of the operation of plastic extruder devices. Manufacturers must be sure that their products or services are manufactured and made with safety features that protect their operators along side the environment. The greatest manufacturers stick to safety standards and regulations and offer safety training which help making use of their clients. Operators must follow safety proper while using the device, including putting on gear this is protective avoiding experience of hot surfaces, and after proper maintenance and cleaning routines.

Making Use Of Plastic Extruder

Utilizing a plastic extruder follows an operation. First, the plastic natural is packed in to the hopper. The material is placed into the extruder barrel and melted by the heating elements. The screw rotates the plastic mixer machine. The die shapes the synthetic into the desired form. This product last then cut and cooled into the desired size. The technique may vary somewhat regarding the product as well as the extruder design.

Provider and Quality of Plastic Extruder

Service and quality are necessary factors in searching for the correct extruder. The top manufacturers offer exemplary customer care, tech support team, and upkeep methods to make their clients certain can run their devices efficiently and safely. Additionally, they provide top-notch goods which is reliable, durable and meet industry standards. The top manufacturers purchase development and research to improve their products and operations.

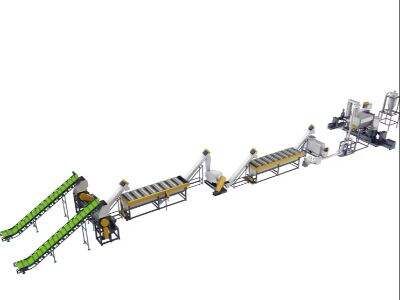

Applications of Plastic Extruder

Plastic extruders are used in a number of industries to produce a true number wide of items. These include pp pipe extrusion line, profiles, sheets, films, cables, and a complete lot more. The extruder is also ideal for recycling waste synthetic services which is new. The absolute most manufacturers effective array of extruders which will meet application is significantly different.

In closing, synthetic extruders are necessary machines for manufacturing plastic products. The most effective 5 manufacturers for plastic extruder offer top-quality products and services with several advantages, innovations, safety features, and services which is often excellent. Seeking the maker you got that right necessary for making certain your production process is efficient, safe, and dependable. As a result of synthetic correct and manufacturer, your company can flourish inside the item plastic competitive.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ