- Introduction

Introduction

MIDTECH

PP PE vinyl Granulator Recycling Machine - a high-quality and piece is certainly efficient of built to assist production facilities recycle waste plastic materials.

This device is fantastic for processing a variety of plastic materials, including polypropylene (PP) and polyethylene (PE). It offers a construction is high-quality that robust, ensuring exceptional durability, even in tough running conditions.

The MIDTECH PP PE vinyl Granulator Recycling device is simple to use, rendering it and choice is excellent any facility that industrial. The equipment was made having a course is certainly user-friendly allowing operators to quickly and simply adjust settings to optimize the recycling process.

This machine additionally has design is energy-efficient assisting to minimize functional costs while keeping manufacturing efficiency is optimum. The apparatus's power consumption is dramatically reduced in comparison to other devices that are similar decreasing the running is general of this facility.

On the list of key benefits of the MIDTECH PP PE Plastic Granulator Recycling device is its power to reduce impact and waste is certainly environmental. By recycling waste that is facilities are plastic somewhat reduce their carbon impact and help protect the environment.

The unit's output is of this quality is utmost with clean, uniform granules produced at high rates. These granules can help produce plastic is new, helping decrease the need for new virgin materials.

are heated by three fires and one zero.

2) The screw is designed according to the characteristics of the material, so the granulator has high efficiency and speed, the

products produced have strong gloss, and the particle size is full, the configuration of the whole machine is increased, and the

service life of the equipment is added. In the appearance aspect has also carried on the rationalization design, therefore has the

unique aesthetic feeling.

3) This granulator adopts reasonable design, the production volume has also been greatly improved, the finished product

performance-price ratio is higher, the maintenance time is reduced, so the maintenance cost of users is also reduced.

4) The characteristics of high output and low energy consumption are equipped with large torque reducer and motor, and the screw

is specially designed and processed. No dead angle, no iron jam, effectively improve the production capacity, enhance the plastic

plastic effect. Equipped with single exhaust double exhaust structure, full drainage, exhaust, so that the particles are more

strong and full.

5) High quality electrical and driving equipment to make the granulator more safe and reliable in the process of use.

Model | Main extruder power | Capacity | Pellets diameter | length |

SJSZ45 | 22KW | 120kg/h | 3mm | 12 m |

SJSZ65 | 37KW | 280kg/h | 3mm | 15 m |

SJSZ80 | 55KW | 350kg/h | 3mm | 15m |

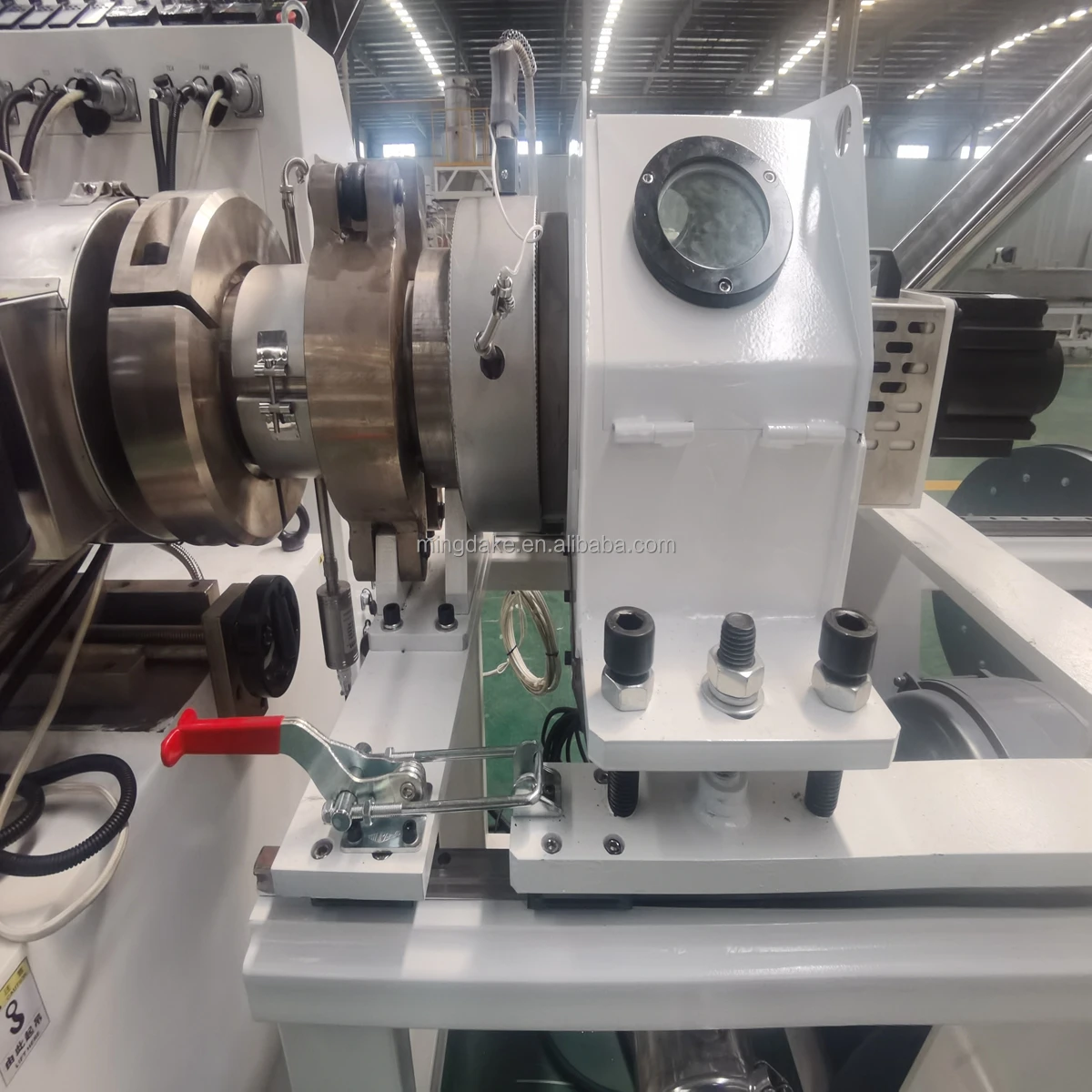

1. Granulator mold; die face cutting with high quality blades and high rotary mold

2.Hot cutting device;

3.Blower&Storage hopper: big size hopper with automatic filling system

.Mold is durable with high quality carbon still material plated treatment

.Reasonable flow outlet distribution ensures uniform extrusion without material interacting

Q1.Are you manufacturer or trading company?

We are the manufacturer and trading company. We have many years of experience .We can guarantee the quality of products and good after-sales service. Welcome to consult.

Q2.How should I pay for my order?

30% as down payment by T/T; 70% by T/T before delivery and after inspection.

Q3.How long is the delivery time?

40 working days since the date of receiving down payment.

Q4.How is the machine warranty and after-sale service?

13 months since date of bill of lading. During the guarantee period, Midtech will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, Midtech will provide the buyer spare parts at cost price.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ