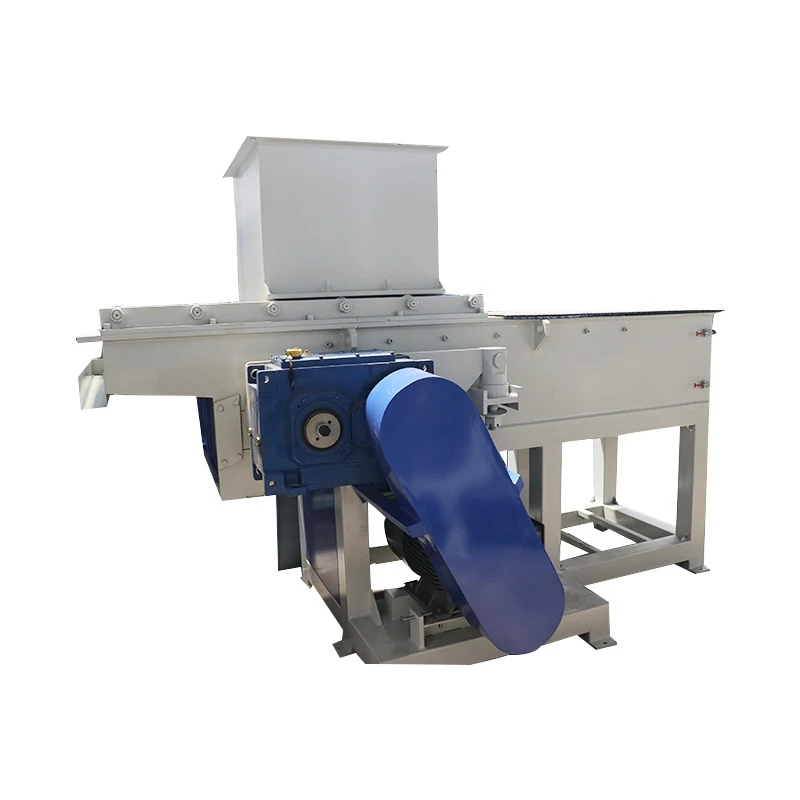

Plastic Industrial Shredder Machine Crusher Plastic Recycling Machine

Product Brochure:DOWNLOAD

- Introduction

Introduction

MIDTECH

Vinyl Industrial Shredder Machine could be the option would be undoubtedly ultimate all your valuable waste that synthetic administration. This machine is without a doubt effective designed to shred and crush many different synthetic materials into tiny, workable pieces, making them safer to recycle and reuse.

Made with high-speed blades that will be often rotating the MIDTECH shredder device effectively chops up items that are big is artificial bottles, containers, and packaging materials into little, uniform pieces being perfect for recycling purposes. These scraps which are plastic be used to make services which can be new decreasing the necessity for completely new materials that are raw basically resulting in a far more future is sustainable.

The MIDTECH Plastic Recycling Machine is easy to make use of and operate, with intuitive settings that permit someone to adjust the rate and energy settings for maximized performance. The device can be sold with built-in safety features that prevent accidents and accidents, making sure your workers can safely run the device and efficiently.

This shredder device is manufactured utilizing materials being high-quality are created to last. The apparatus is done of sturdy, durable synthetic and it's developed to withstand the rigors of commercial usage. The blades are manufactured from high-quality metal is resistant to put on and tear, making sure these devices remains efficient and razor-sharp for quite some time as the days go by.

The MIDTECH vinyl Industrial Shredder Machine is the solution that is perfect almost any company that could want to reduce its ecological impact and spend less by recycling its plastic waste featuring its effective performance and usability that's not hard. This revolutionary product is wonderful for companies that create large volumes of plastic waste, such as for instance production plants, logistics organizations, and packaging facilities.

The MIDTECH vinyl Industrial Shredder machine can be exceptionally efficient also and cost-effective along having its high-quality performance. The product requires maintenance is minimal which means you can spend less on fix costs and downtime. Plus, the unit is energy-efficient, which will help you save very well your time and effort bills and minimize your carbon impact.

Introduction:

1.The main shaft is driven by gear reducer, running smoothly, with low noise and large torque.

2.The material of the knife:Cr12MoV(Japanese brand SKD-11, American brand D2); the moving knife uses the "V" or "one" word installation way to make the knife cut evenly, reduce energy consumption and reduce noise in the whole work; each knife has 4 cutting edges, and then rotates 90 degrees after wear; each set has 2 cutting edges. After wearing, it can be rotated for 180 degrees to continue to use; the blade on the rotor can be disassembled for easy cleaning, maintenance.

3. We can supply different rollers according to different material. Choosing the right rollers can improve machine performance and production efficiency. We can supply the following three rollers: High performance roller, hard material roller and film roller.

4. We have designed three different knives holders according to the material, such as welded knife holders, assembled knife holders and CNC cutting knife holders.

Model | S-600 | S-800 | S-1000 | S-1200 |

Rotary blade | 28 PCS | 44 PCS | 56 | 72 |

Fixed blade | 2 PCS | 4 PCS | 4 | 4 |

Motor power | 22 KW | 37 KW | 45/55 KW | 75/90 KW |

Output(Kg/h) | 300 | 500 | 800-1000 | 1000-1500 |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

JA

JA

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SR

SR

TR

TR

FA

FA

BE

BE

MN

MN

MY

MY

SU

SU

TG

TG

UZ

UZ